Have you ever looked at your cramped small home and wondered how to create more storage without sacrificing precious floor space—and what if the solution was literally hanging on your walls?

DIY Floating Shelves for Small Home. This guide explores the transformative power of floating shelves, offering practical steps and creative ideas to enhance storage, display cherished items, and maximize space in any compact living area.

The Magic of Floating Shelves: Maximizing Space in Small Homes

Living in a small home, whether it is an apartment, a tiny house, or a compact urban dwelling, often presents a unique set of challenges. Storage is paramount. Every inch counts. Traditional bulky bookshelves or wall units can overwhelm limited space, making rooms feel even smaller. This is precisely where the magic of DIY Floating Shelves comes into play. They offer an elegant, space-saving solution that combines functionality with minimalist aesthetics.

Floating shelves appear to emerge seamlessly from the wall, without visible brackets or supports. This creates a clean, uncluttered look that enhances the perception of space. They maximize vertical storage, turning unused wall areas into valuable display or organizational zones. This is crucial for small homes where floor space is a premium. They can hold books, decorative items, plants, or even kitchen essentials, serving diverse needs in various rooms.

Embracing DIY Floating Shelves empowers homeowners to customize their storage solutions precisely. It offers a cost-effective way to refresh a room. It adds significant value and functionality without the bulk of traditional furniture. This guide provides a step-by-step approach to installing these ingenious shelves, transforming cluttered areas into beautifully organized and visually expansive spaces.

Quick reflection: What room in your home needs the most storage help right now—your living room, kitchen, or bedroom?

Key Considerations Before Installing DIY Floating Shelves

Before you pick up your tools, careful planning ensures your DIY Floating Shelves project is successful, safe, and meets your aesthetic and functional goals.

Wall Type and Weight Capacity: The Foundation of Safety

Understanding your wall type is crucial for determining how much weight your DIY Floating Shelves can safely hold.

Drywall (Plasterboard): Requires finding wall studs (vertical wooden or metal frames behind the drywall) for secure mounting. If no studs are available, use heavy-duty drywall anchors specifically rated for the weight you intend to place on the shelf.

Plaster and Lath: Older homes might have this. It is strong but harder to drill. Locate studs or use appropriate anchors.

Brick or Concrete: Requires specialized masonry drill bits and anchors. These walls offer excellent support.

Never overload your shelves. A clear understanding of weight limits prevents accidents and damage. This is paramount for DIY Floating Shelves.

Shelf Material and Finish: Aesthetics and Durability

The material and finish of your shelves significantly impact the final look and durability.

Solid Wood: Offers warmth, natural beauty, and can be stained or painted. Popular choices include pine, oak, or maple.

Plywood/MDF: More affordable, good for painting, but might require edge banding for a finished look.

Laminated Wood/Melamine: Cost-effective, easy to clean, comes in various colors, but can chip.

Glass: Creates a light, airy feel; best for lighter items.

Consider the room’s style, the intended use (heavy books vs. light décor), and ease of maintenance when choosing your material.

Bracket System: The Invisible Support

The “floating” effect comes from hidden or minimally visible bracket systems.

Blind Shelf Supports: These are metal rods that embed directly into the shelf and then into the wall studs, making them completely invisible. Ideal for a true floating look.

Hidden Brackets: Small, discreet brackets that are mounted to the wall first, then the shelf slides over them.

Heavy-Duty Wall Anchors: For situations where studs are not available, specialized anchors can provide support, but always check their weight rating.

The choice of bracket depends on your wall type, desired weight capacity, and aesthetic preference.

Placement and Height: Functionality and Visual Appeal

Carefully plan the placement and height of your DIY Floating Shelves. Consider:

Function: Will they hold books (eye-level)? Display art (gallery height)? Or store kitchen items (above counters)?

Spacing: Ensure enough vertical space between shelves for items you intend to store.

Visual Balance: Consider the overall composition of the wall. Avoid overcrowding.

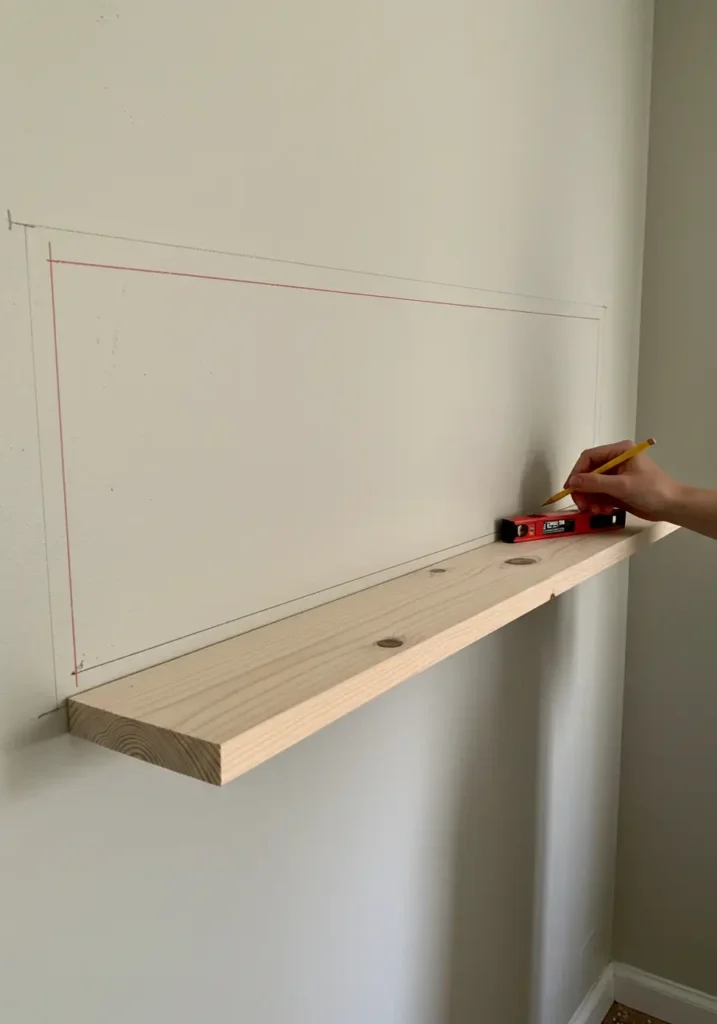

Measure precisely and use a level to mark placement. This ensures aesthetic appeal and optimal functionality.

Quick reflection: Have you ever attempted a DIY home project before, or will floating shelves be your first hands-on installation experience?

DIY Floating Shelves: Step-by-Step Installation Guide

Installing DIY Floating Shelves requires basic tools and a methodical approach. Follow these steps for a secure and professional-looking result.

Step 1: Gather Your Tools and Materials

Before starting your DIY Floating Shelves project, collect all necessary items:

- Shelf boards (pre-cut or cut to size)

- Hidden shelf supports/brackets (appropriate for your wall type and weight)

- Stud finder

- Tape measure

- Pencil

- Level

- Drill and drill bits (appropriate for your wall type)

- Screwdriver or impact driver

- Safety glasses

- Optional: Painter’s tape, sandpaper, paint/stain.

Having everything ready streamlines the process.

Step 2: Plan and Mark Placement

Decide on the exact placement and height of your DIY Floating Shelves. Use a pencil and tape measure to mark the desired height on the wall. Use a stud finder to locate wall studs along the marked line. Mark the center of each stud. Aim to attach your shelf supports to at least two studs for maximum stability. If no studs align, plan to use heavy-duty wall anchors. Use a long level to ensure your marks are perfectly horizontal. Accuracy here prevents a crooked shelf.

Step 3: Install the Support Brackets

This is the most critical step for the stability of your DIY Floating Shelves.

For blind shelf supports: Drill pilot holes into the marked stud locations (or for anchors). Insert anchors if not using studs. Securely screw the metal support rods directly into the studs or anchors. Ensure they are perfectly level and spaced according to your shelf design.

For hidden wall brackets: Mount the brackets securely to the wall studs (or heavy-duty anchors) using appropriate screws. Double-check levelness.

Follow the manufacturer’s specific instructions for your chosen bracket system. Secure mounting is paramount for safety.

Step 4: Prepare the Shelf Board (If Using Blind Supports)

If using blind shelf supports that embed into the shelf, you need to prepare the shelf board. Measure the exact spacing of your installed support rods. Mark corresponding points on the back edge of your shelf board. Using a drill bit slightly larger than the support rods, drill holes into the back edge of the shelf to the required depth. Ensure these holes are perfectly straight and level to allow the shelf to slide onto the rods smoothly.

Step 5: Mount the Shelf

For blind shelf supports: Carefully slide the shelf board onto the protruding metal rods, ensuring it fits snugly and flush against the wall. You might need to gently tap it with a rubber mallet.

For hidden wall brackets: Slide the shelf board over the mounted brackets until it is secure. Some systems may require small screws from the underside of the shelf into the bracket for added security.

Check the shelf again with your level to ensure it is perfectly straight. Your DIY Floating Shelves are now installed.

Step 6: Finish and Decorate

Once installed, you can finish your DIY Floating Shelves. This might involve applying paint or stain (if not already done). Allow any finishes to cure completely. Then, begin decorating! Place your books, decorative items, plants, or organizational bins. Distribute weight evenly along the shelf. Step back and admire your new, transformed space.

Quick reflection: Which step of the installation process seems most challenging to you—finding studs, drilling precisely, or styling the finished shelves?

Budgeting for DIY Floating Shelves: Cost-Effective Storage

Creating DIY Floating Shelves is generally a very budget-friendly project. Your costs primarily involve materials and tools, with labor being your own.

Affordable Options (Under $50 per shelf)

For budget-friendly DIY Floating Shelves, explore common lumber like pine or MDF. Use basic paint or a simple stain for finishing. Opt for affordable, yet sturdy, hidden wall brackets if blind supports are too complex or costly. You can find these materials at local hardware stores. This approach provides significant storage enhancement for very little cost.

Consider using reclaimed wood for a rustic, eco-friendly option. This can further reduce material costs.

Mid-Range Materials (Between $50-$100 per shelf)

A mid-range budget allows for higher quality wood (e.g., oak, maple for shelves) or more sophisticated blind shelf supports. You might also invest in higher-quality paint or stains. This tier provides improved durability and a more polished aesthetic. It offers a good balance of cost and long-term value for your DIY Floating Shelves.

This level allows for a more refined look that elevates the room’s design.

Premium Finishes and Customization (Over $100 per shelf)

A larger budget opens doors to custom-milled shelves from exotic hardwoods, specialized finishes, or complex, multi-tiered floating shelf systems. This level allows for a truly bespoke look that integrates seamlessly into a high-end design. It might also cover renting specialized tools for precision cuts or finishes. This represents a significant investment for ultimate customization and luxury.

Also Read: 15 Smart Small Apartment Organization ideas

Caring for Your DIY Floating Shelves: Maintaining Beauty and Function

Proper care ensures your DIY Floating Shelves maintain their beauty, stability, and functionality for years. Consistent maintenance protects your effort and investment.

Regular Cleaning and Dusting

Dust your floating shelves regularly with a soft cloth to prevent buildup. For painted or sealed shelves, wipe clean with a damp cloth and mild soap for smudges. For unfinished or natural wood shelves, avoid excessive moisture. Promptly wipe up any spills. Regular cleaning preserves the shelf’s finish and keeps your displayed items looking fresh.

Respect Weight Limits and Distribute Load Evenly

Never overload your DIY Floating Shelves beyond their weight capacity. This is critical for safety and to prevent damage to the shelf or wall. Distribute items evenly along the shelf, placing heavier items closer to the wall supports. Avoid concentrating heavy weight on one end. This practice maintains stability and prevents sagging.

Periodic Checks for Stability

Periodically check the stability of your DIY Floating Shelves. Gently test for any wobbling or looseness. If you notice any movement, re-tighten screws, or if using anchors, inspect them for wear. Address any signs of instability promptly to prevent accidents. This proactive check ensures long-term safety and peace of mind.

Quick reflection: What will you display on your floating shelves—books, plants, family photos, or a curated collection of decorative objects?

Latest Innovations in Shelving and Home Storage

The world of home organization and DIY continually evolves, bringing new tools, materials, and technologies that simplify storage solutions. These innovations enhance the possibilities for DIY Floating Shelves and other storage options.

Modular and Adaptable Systems

Manufacturers develop modular shelving systems that allow for easy reconfiguration. Components snap together or adjust without tools, offering unparalleled adaptability. This means you can change shelf heights, add sections, or alter layouts as your needs evolve. This flexibility makes them a long-term solution for changing storage requirements.

Smart Storage Solutions and Integrated Lighting

Innovation extends to smart storage. This includes shelves with integrated LED lighting that can be controlled via apps, enhancing both aesthetics and functionality. Some systems might incorporate hidden charging ports or smart home sensors. This blends technology seamlessly into your storage solutions.

Sustainable Materials and Eco-Friendly Options

A growing trend focuses on environmentally conscious shelving materials. This includes shelves made from recycled plastics, reclaimed wood, bamboo, or other rapidly renewable resources. These choices reduce environmental impact and often feature unique textures and finishes. This allows DIYers to create sustainable and stylish storage.

Making Your Final Decision on DIY Floating Shelves

Creating DIY Floating Shelves is a rewarding project that significantly enhances storage and aesthetics in any small home. Your success depends on careful planning, precise installation, and ongoing maintenance.

Prioritize understanding your wall type and weight capacity. This is critical for safety and stability. Choose shelf materials and bracket systems that align with your aesthetic vision and functional needs.

Consider precise placement and height. Plan how the shelves will integrate with your existing decor and serve their intended purpose. Measure multiple times before drilling.

Do not overlook the importance of proper tools. Having the right drill, level, and fasteners makes the installation process smoother and ensures a professional-looking result.

Remember, DIY Floating Shelves transform unused wall space into functional beauty. When installed thoughtfully, they maximize your home’s potential, creating a more organized, spacious, and inviting living environment.

Unlock Your Space: The Power of DIY Floating Shelves

DIY Floating Shelves offer an elegant and highly effective solution for maximizing storage and enhancing aesthetics in any small home. By following practical steps and choosing suitable materials, you transform empty walls into functional and beautiful display areas.

Take time to plan meticulously. Choose the right wall type and ensure proper installation for safety. Remember that careful execution leads to a professional-looking result.

As you embark on this rewarding project, remain patient and precise. Your efforts will yield significant improvements in organization and visual appeal.

By applying these insights, you unlock your home’s potential. You create a more spacious, organized, and inviting living environment. You truly benefit from the magic of DIY Floating Shelves.

Have you already installed floating shelves in your home, or are you planning your first DIY project—and what’s your biggest concern about getting started?

Share your DIY experiences, questions, or creative shelf styling ideas in the comments below—I’d love to see how you transform your small space!

Frequently Asked Questions About DIY Floating Shelves

What are DIY Floating Shelves?

DIY Floating Shelves are shelves that appear to be directly attached to a wall without visible supports or brackets. They create a clean, minimalist look and are often installed by homeowners themselves to maximize vertical storage and display space.

How much weight can DIY Floating Shelves hold?

The weight capacity of DIY Floating Shelves depends on the wall type (studs vs. drywall only), the type of mounting hardware (brackets, anchors), and the shelf material. Shelves mounted into studs with proper hardware can hold significantly more weight than those using only drywall anchors. Always check manufacturer ratings.

What tools do I need for DIY Floating Shelves installation?

You typically need a stud finder, tape measure, pencil, level, drill and appropriate drill bits for your wall type, screwdriver/impact driver, and safety glasses. Optional tools include a miter saw (if cutting your own shelves) and a rubber mallet.

Can DIY Floating Shelves be installed on any wall type?

DIY Floating Shelves can be installed on most wall types (drywall, plaster, brick, concrete), but each requires specific drilling techniques and mounting hardware. Finding wall studs is ideal for maximum support, especially for heavier items.

How can I ensure my DIY Floating Shelves are level?

To ensure your DIY Floating Shelves are level, always use a high-quality level when marking your pilot holes and installing the brackets. Double-check levelness at each stage of the installation process. Precision in marking and drilling is key for a perfectly straight shelf.

This Post Contains Affiliate Links

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.